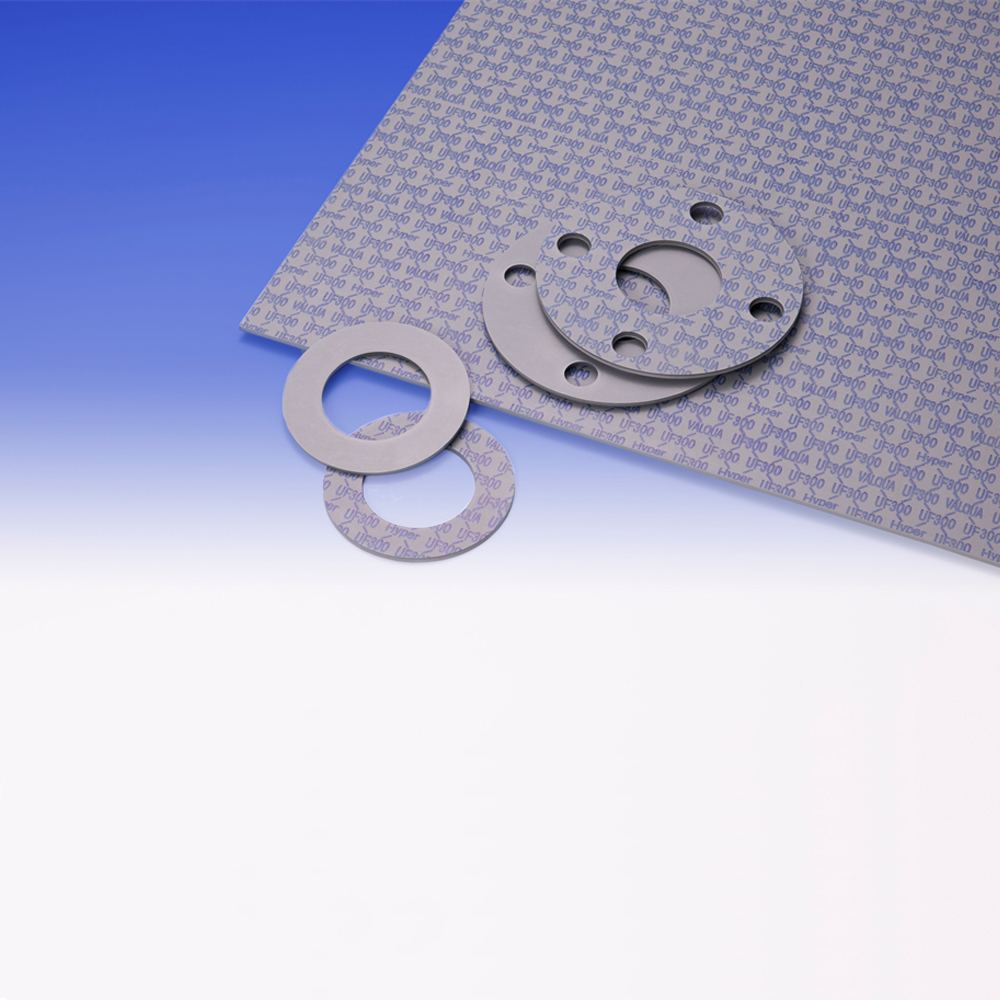

| Suitable fluids | Water, seawater, hot water, steam, air, acid (includes strong acid), alkali (includes strong alkali), salt aqueous solution, oils, alcohol, aliphatic solvent and its vapor, and various types of gas, etc. |

| Unsuitable fluids | Polymerizable monomer,toxic gas |

| Applications | Joint sections of cover flanges and nozzles and the like for pipe flanges, valve bonnets, towers & tanks, ovens, pressure vessels and heat exchangers used in various factories including power stations, oil refineries, steel plants and shipyards |

| Main Component | PTFE, silicon carbide |

| Color/Print | Gray / Blue |

설계 데이터

- 허용 범위

온도 및 압력 분류는 개별 서비스 한계를 보여줍니다.

-

Temperature (°C) Pressure (MPa) -200~300 3.5 - 치수

Thickness (mm) Size (mm) 1.0 1270×1270 1.5, 2.0,3.0 1500×1500 - 설계 기준

JIS B 8265 부록 G에 정의된 압축 비석면 섬유 시트의 값은 고성능 비석면 시트의 m 및 y 값에 적용할 수 있습니다.

Thickness

(mm)Gasket factor

“m”Minimum design seating stress

“y”(N/mm2)3.0 2.00 11.0 1.5 2.75 25.5 1.0 3.50 44.8 - 추천 조임 응력(MPa)

추천 조임 응력은 내부 유체로 인한 엔드포스를 고려하지 않은 표준 조건에서 필요한 압력입니다. 개스킷의 접촉 면적에 대한 응력입니다.

| Fluid | Recommended tightening stress (MPa) |

| Liquid | 25.5 |

| Gas | 35.0 |

고성능 비석면 시트의 응력 변형 특성

(시험편 치수:JIS 10K 25A t =1.5mm)

Tiếng Việt

Tiếng Việt English

English 日本語

日本語