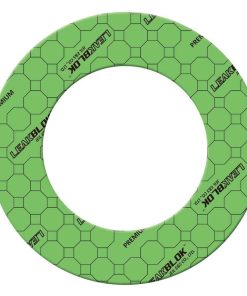

材料特性

| Color | Blue(Black Printed) |

| Composition | Aramid Fiber + NBR Binder |

| Fluids Service | Portable Water, Oils, Fuels, Salt Solution, Mild acids and alkalis, gas line |

| Pressure | Short-term peak 80bar(1160 psi) |

| Temperature | Continuous -150℃(-238°F) ~ 220℃(428°F) Short-term peak -196℃(-321°F) ~ 350℃(660°F) |

| pH range | 4-11 |

| Thickness(mm) | 0.8 ~ 3.2(mm) |

| Size(mm) | 1270(W)×1270(L), 1500(W)×1500(L) Available in Rolls. |

| Certificates | Lloyd’s & ABS Type Approval , TA-Luft(VDI 2440), WRAS, BS 7531 Grade Y

Fire Endurance Test(ISO 19921 & 19922) |

サービス範囲

| Area A | Satisfactory area subject to chemical compatibility |

| Area B | Usually suitable but required technical recommend by Khong Lieng |

| P×T(Max) | psi ×°F(bar×°C) / 496,480(17,600) |

物理的特性

| Test Method | Description | LEAKBLOK® P200 |

| ASTM D792 | Density (g/cm3) | 1.9 |

| ASTM F152 | Tensile Strength Across grain. MPa (kgf/mm2) |

15.0(1.53) |

| ASTM F36 Procedure J |

Compressibility (%) Recovery (%) |

9 71 |

| DIN 3535 – 6 | Gas permeability (ml/min) | ≤ 0.01 |

| DIN 52913 | Relaxation Stress(MPa) -50MPa 16 hours @175°C |

38.2 |

| BS 7531 | Relaxation Stress(MPa) -40MPa 16 hours @300°C |

23.7 |

| VDI 2440 (TA-Luft) |

Leak rate ( mbar·l /(s·m) ) -at 150°C 48 hours |

2·10-8 |

吸収特性

| Test Method ASTM F146 |

Description | LEAKBLOK® P200 |

| at 150°C×5hrs ASTM Oil no 3 |

Thickness Increase (%) | 3 |

| at 20~30°C×5hrs ASTM Fuel B |

Thickness Increase (%) Weight Increase (%) |

6 9 |

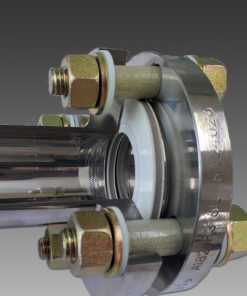

ガスケット設計データ

| Thickness (mm) | Gasket Factor (m) | Min. Design Seating Stress(y) Kgf/cm2 (psi) |

| 3.2 | 2.00 | 112(1600) |

| 1.6 | 2.75 | 260(3700) |

| 0.8 | 3.50 | 457(6500) |

すべてのデータは、通常の厚さ 1.5 mm の値です。

先進技術の LEAKBLOK® は、従来のカレンダー製造方法とは全く異なります。

環境に優しい無溶剤プロセスで特別に発明されました。

以前の製品と比較して、低い応力でも高い耐久性と優れた性能を示します。

蒸気およびクリーンパイプラインでの使用に適しており、液体汚染からの優れた保護を提供します。

警告

- 最大温度と圧力で同時に使用できません。

- 指針のみであり、この範囲を超える場合はお問い合わせください。

- 特定の指示がない限り、ガスケットを再利用しないでください。

- ガスケットとシール化合物を併用しないでください。これにより性能が低下する可能性があります。

- 特殊な蒸気パイプラインおよび爆発ガスのアプリケーションについては、Sval にご相談ください。

- 最大長については Sval の営業チームにご確認ください。

Tiếng Việt

Tiếng Việt English

English Korean

Korean