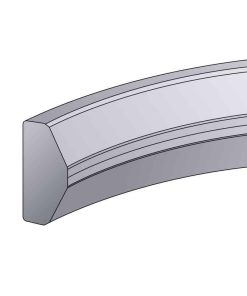

Material

Carbon fibres and special heat resistant additives bonded with NBR.

pT diagrams

The Klinger pT diagram provides guidelines for determining the suitability of a particular gasket material for a specific application based on the operating temperature and pressure only. Always refer to the chemical resistance of the gasket to the fluid.

1. In area one, the gasket material is normally suitable subject to chemical compatibility.

2. In area two, the gasket materials may be suitable but a technical evaluation is recommended.

3. In area three, do not install the gasket without a technical evaluation.

Technical Data – Typical values for 2mm thickness

| Compressibility ASTM F 36 J | 11% |

| Recovery ASTM F 36 J min. | 60% |

| Stress relaxation DIN 52913 | |

| 50 MPa, 16 h/300°C | 32MPa |

| 50 MPa, 16 h/175°C | 35MPa |

| Stress relaxation BS 7531 40 MPa, 16 h/300°C |

30MPa |

| Klinger cold/hot compression, 50 MPa | |

| thickness decrease at 23°C | 10% |

| thickness decrease at 300°C | 15% |

| Tightness according DIN 3535/6 | 0.1mg/sm |

| Thickness increase ASTM F 146 | |

| oil JRM 903: 5 h/150°C | 3% |

| fuel B: 5 h/23°C | 5% |

| Density | 1,6g/cm3 |

Meets the technical requirements of BS 7531:2006 Grade AX

Dimensions of the standard sheets

Sizes: 1000 x 1500 mm, 2000 x 1500 mm.

Thicknesses: 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 3.0 mm; other thicknesses and sizes on request.

Tolerances: thickness ± 10%, length ± 50 mm, width ± 50 mm.

Surfaces

KLINGERSIL® gasket materials are generally furnished with surfaces of low adhesion. On request, graphite facings and other surface finishes on one or both sides are also available.

Function and durability

The performance and service life of KLINGER gaskets depend in large measure on proper storage and fitting, factors beyond the manufacture’s control. We can, however, vouch for the excellent quality of our products. With this in mind, please also observe our installation instructions.

Tiếng Việt

Tiếng Việt 日本語

日本語 Korean

Korean