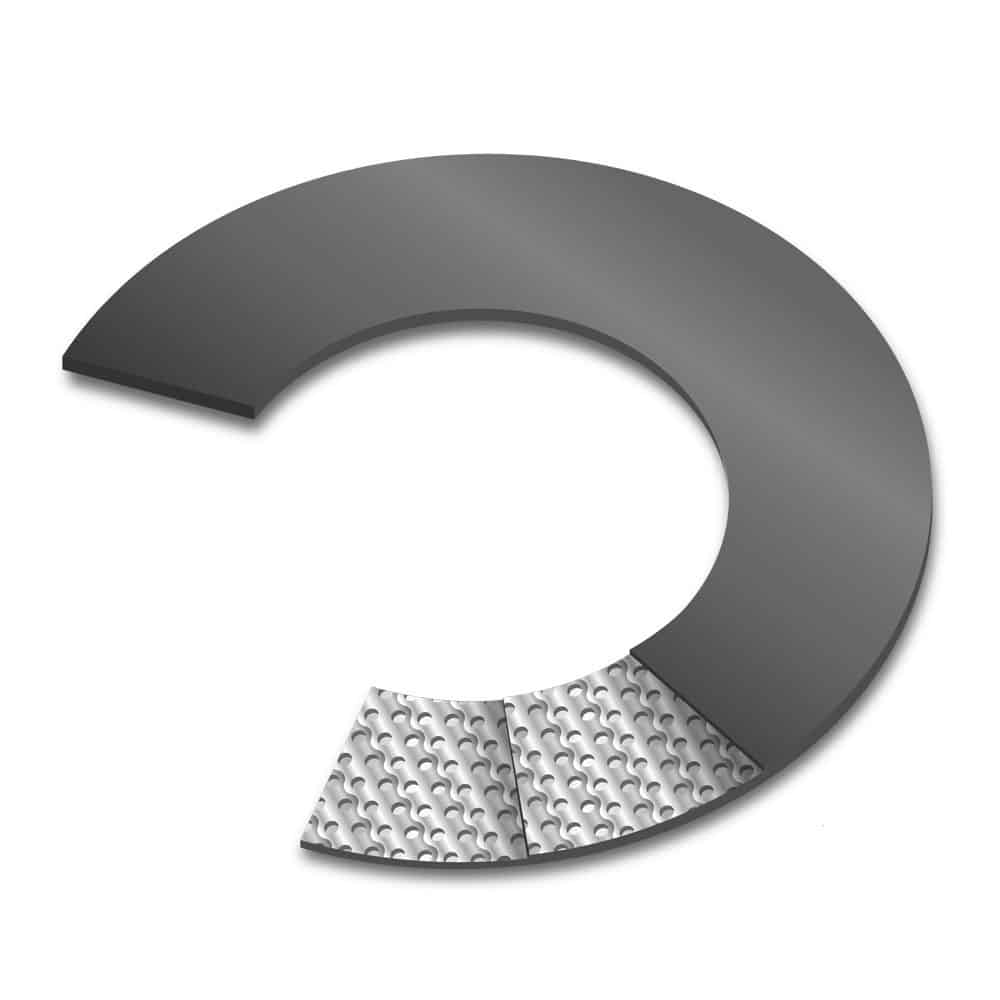

재료

순수 박리 흑연에 탱글 스테인리스 강판 보강재.

pT 다이어그램

Klinger pT 다이어그램은 작동 온도와 압력만을 기준으로 특정 응용 분야에 대한 특정 개스킷 재료의 적합성을 결정하기 위한 지침을 제공합니다. 항상 유체에 대한 개스킷의 내화학성을 참조하십시오.

- 영역 1에서 개스킷 재료는 일반적으로 화학적 호환성에 따라 적합합니다.

- 영역 2에서 개스킷 재료는 적합할 수 있지만 기술 평가가 권장됩니다.

- 영역 3에서 기술 평가 없이 개스킷을 설치하지 마십시오.

기술 데이터 – 1.5mm 두께의 일반적인 값

| Compressibility (ASTM F36J) | 35% |

| Recovery (ASTM F36J) | 20% |

| Stress relaxation DIN 52913 50 MPa, 16 h/300°C |

48N/mm2 |

| Stress relaxation BS 7531 40 MPa, 16 h/300°C |

38N/mm2 |

| Leachable chloride | <40ppm |

| Graphite purity | >98% |

| Gas leakage (DIN 3535/6) | <1.0ml/min |

| Thickness increase after immersion in oil JRM 903: 5 h/150°C |

<2% |

| Density | 1.0g/cm3 |

| Standard insert: 316 | 0.1mm |

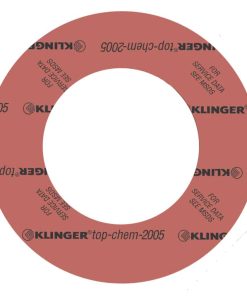

표준 시트의 치수

크기: 1000 x 1000mm, 1500 x 1500mm

두께: 0.8mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm

기능 및 내구성

KLINGER 개스킷의 성능과 수명은 대부분 적절한 보관 및 장착에 달려 있으며, 이는 제조업체의 통제 범위를 벗어난 요소입니다. 그러나 당사는 당사 제품의 우수한 품질을 보증할 수 있습니다. 이를 염두에 두고 설치 안내를 준수하십시오.

Tiếng Việt

Tiếng Việt English

English 日本語

日本語