Application of Maxiprofile Gasket

- Standard flanges, Heat exchanger and vessel applications

- High and low temperatures

- Pressures of up to 400 bar

- Low bolt loads

- Narrow flange widths

- Damaged flanges

- Have a wide range of seating stresses under which the seal is effected and maintained.

- Can be used when there is insufficient bolt load to seal conventional gasket materials.

- Easy to handle and fit

- Suitable for a wide range of operating conditions.

- The soft facing layer prevents damage to the flange.

- Provide a high integrity seal including in thermo cycling and shock loading conditions.

- Can be refurbished with a new facing layer and reused.

- Can be manufactured in a very wide variety of sizes and shapes according to customer design

Styles of Maxiprofile’s available.

All can be supplied with bars to suit heat exchanger configurations.

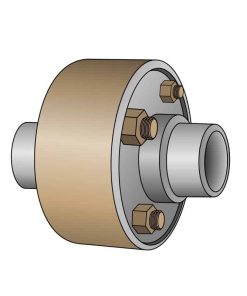

CA1,2&3 Convex profiled joints in the same style as LA 1, 2 and 3. The convex profile is designed to assist sealing in bolt load applications.

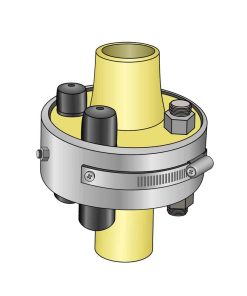

STYLE LA1

Lateral profiled joint with guide ring for raised and flat face applications

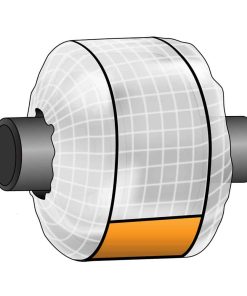

STAYLE LA2

Lateral profiled joint without guide ring for male and female, tongue and groove and groove flanges

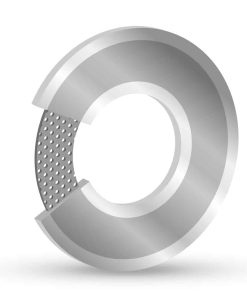

STAYLE LA3

Lateral profiled joint with floating guide ring for raised and flat face applications.

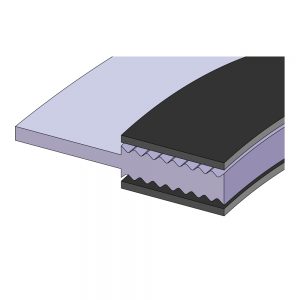

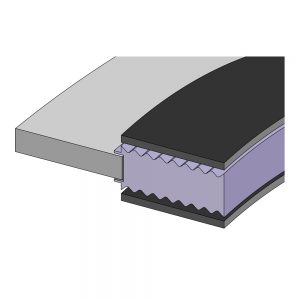

Standard core design

The core design for the standard Maxifrofile style 109 is parallel and shown below

Facing materials

Expanded graphite is the most common facing material used for Maxiprofile gaskets. However, other materials can be used, such as PTFE for chemically aggressive duties or mica for high temperature duties.

Facing materials minimum and maximum operating temperatures

| Graphite | -200 to 500°C |

| PTFE | -200 to 260°C |

| Mica | to 1000°C |

| KLINGERSIL®C-4430 | -196 to 250°C |

Core material maximum temperatures

| 316L Stainless Steel | 800°C |

| 304 Stainless Steel | 650°C |

| Duplex UN S31803 | 800°C |

| 347 Stainless Steel | 870°C |

| 321 Stainless Steel | 870°C |

| Super Duplex | 600°C |

| Inconel 600 & 625 | 1000°C |

| Incoloy 825 | 600°C |

| Monel 400 | 800°C |

| Nickel 200 | 600°C |

| Titanium Gr7 & Gr2 | 500°C |

| Hastelloy B-2/B-3 | 700°C |

| Hastelloy C-276 | 700°C |

| Alloy 20 | 600°C |

For all other core materials please consult sval

Tiếng Việt

Tiếng Việt 日本語

日本語 Korean

Korean