Key function of insulating gaskets:

- Used to electrically isolate sections of pipe work

- Designed to minimise electro-chemical erosion

- Comprising materials with high dielectric strength

- Manufactured to suit flanged joints to ASME, BS, DIN and customer designs

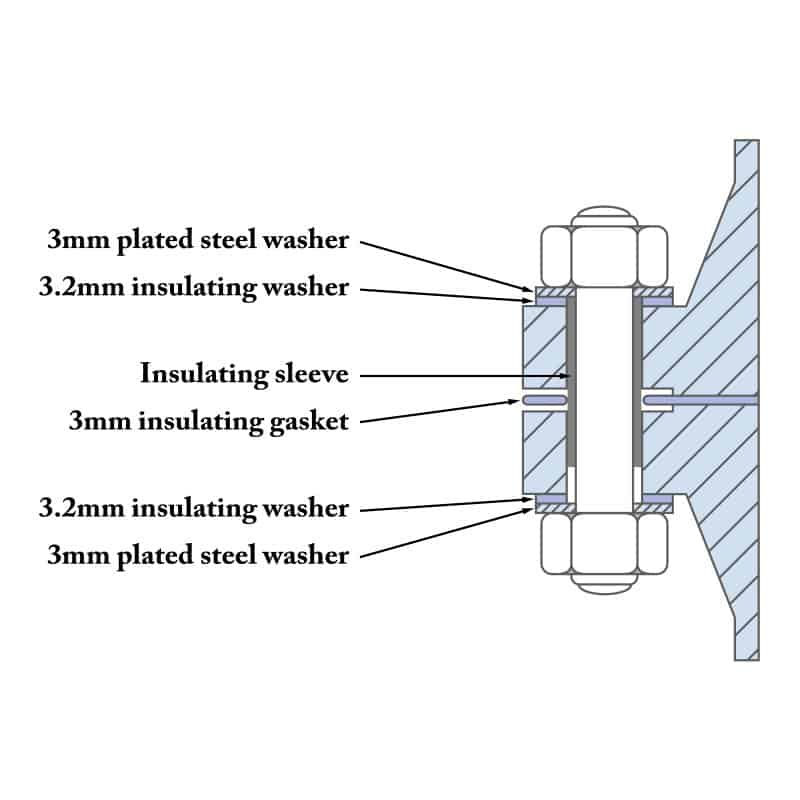

Style E – Full face gasket insulating set assembly

Suitable for flat and raised face flanges. This style minimises the ingress of conductive foreign matter and reduces the risk of bridging.

Typically used on oil and hydrocarbons where flange insulation is a requirement. Manufactured from materials with high dielectric strength to ensure minimum electrical contact between flanges

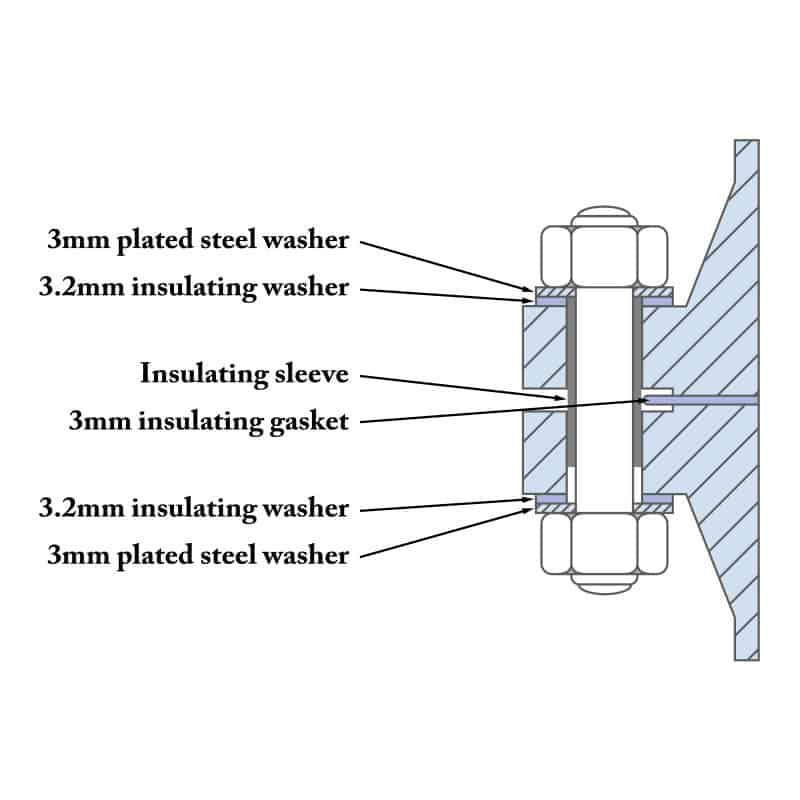

Style F – Inside bolt locating gaskets insulating set assembly

Utilises a RF gasket which centrally locates within the bolts Typically used on oil and hydrocarbon where flange insulation is a requirement. Manufactured from materials with high dielectric strength to ensure minimum electrical contact between flanges

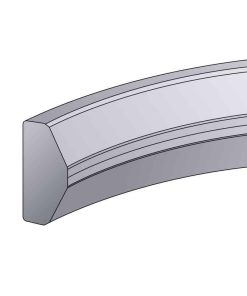

Style D – Ring Joint Gasket

Reinforced phenolic ring type joint gasket. Available with a choice of insulating sleeves and washers: Unless otherwise specified Reinforced phenolic will be supplied. Other materials on request. Care must be taken during installation of this gasket so that it is not overstressed during bolt up.

High Pressure Spring Energised PTFE Insulation Gasket

This gasket is a high reliability gasket used for both insulating and general sealing purposes in a very critical services. The gasket is suitable in all services up to and including ANSI 2500# and API 15,000# classes. The gasket is manufactured from a machined metallic core with high-strength glass-fibre reinforced epoxy resin insulating faces.

Supplied with high-strength G10 insulating washers and sleeving to resist the forces present in high pressure applications and zinc-plated carbon steel washers to spread the load across the insulating washers during installation.

Spring-energised PTFE or Viton sealing elements are available Corrosion resistant metallic core. Also available with high-temperature faces manufactured from G-11 epoxy resin.

Also available in style VCFS which is fire safe according to API 6FB.

Based on the VCS design and is manufactured with a stainless steel core with glass fibre reinforced epoxy facings with a spring energised PTFE seal.

The VCSF gasket features an additional Fire safe coated E ring. VCFS can be used on both raised face and RTJ flanges.

Technical Specifications for Klinger manufactured Insulating gaskets sets

| Component | 1 | 2 | 3 | 4 | 5 | 6 |

| Dielectric Strength 1 kV/mm | 19.8 | 7.8 | 5.5 | 16.6 | 5.87* | 13.9* |

| Water Absorption % | 1.6 | 1.0 | 1.0 | 10.6 | 0.5 | 0.5 |

| Max. Operating Temp. °C | 107 | 107 | 107 | 400 | 260 | 260 |

- Test according to ASTM D149 in transformer oil. To convert from kV/mm to V/mil multiply by 25.4. *Test according to ASTM D149 in air.

- Recommended maximum temperature in air for electrical isolation purposes.

Component Material

1 Type E and F Flat Gasket 3.2mm thick neoprene faced phenolic

2 Insulating Washer 3.2mm thick reinforced phenolic

3 Insulating Sleeve 0.8mm thick phenolic

4 Type E and F Flat Gasket 3.0mm thick KLINGERSIL®C-4430. Rated fire safe

5 Type E and F Flat Gasket 3.0mm thick KLIGER®top-chem 2000. Rated fire safe

6 Type E and F Flat Gasket 3.0mm thick KLINGER®top-chem 2003.

Tiếng Việt

Tiếng Việt 日本語

日本語 Korean

Korean